Closing the Loop: Rethinking the Economy and Saving the Planet

Those of us in the sustainability space have been talking about “circularity” or the “circular economy” since at least the early 2000s. However, the idea of a circular economy was first put forth in an essay by economist Kenneth E. Boulding in 1966, entitled The Economics of the Coming Spaceship Earth. Here, he explained that “we should be in a ‘cyclical’ system of production.” Boulding theorized that the open economy was the “cowboy” economy where there are unlimited resources; and that the closed economy was the “spaceman” economy where Earth might be considered “a single spaceship without unlimited resources for anything...Therefore, man must find himself in a cyclical ecological system.”

Circularity Today

Many of us are working to find ways to extend the life cycle of almost every product - whether it be seltzer water or dairy foods. These companies are looking to move away from a traditional linear economic model to one that is more circular, providing other benefits during the full product life cycle.

According to the Ellen MacArthur Foundation, “The circular economy is a systems solution framework that tackles global challenges like climate change, biodiversity, loss, waste, and pollution. It is based on three principles driven by design: eliminate waste and pollution, circulate products and materials at their highest value, and regenerate nature.”

At its base level, it comes down to limiting waste in the manufacturing process and finding ways to extend the life cycle of every product we use.

For example, let’s look at the environmental impact of a single smartphone. According to Deloitte Insights, “A brand-new smartphone generates an average of 85 kilograms in emissions in its first year of use. Ninety-five percent of this comes from the manufacturing processes, including the extraction of raw materials and shipping.” The EPA’s greenhouse gas emissions calculator shows that this is the equivalent of driving 211 miles in a car. When you consider that there are more than 4 billion smartphones in use in 2022, including the one that you might be reading this article on right now, that’s a lot of emissions created from one single product. The obvious circularity question is what parts of that smart phone could be put into constructive reuse after the phone has served its initial purpose?

Companies in all industries are increasingly looking for ways to create circularity in their operations. Food and beverage manufacturers are no stranger to the pursuit of a circular economy, with a rise in tactics such as upcycling, animal feed, and component recycling becoming part of the new norm.

The Food and Beverage Innovators Working to Close the Loop

The food and beverage industry offers unique opportunities for dramatic greenhouse gas recycling by investing in the circularity of its core product and packaging. As most people know discarded food either ends up in landfills or at incinerators and is one of the largest greenhouse gas contributors by industry type, even larger than the aviation industry. Remarkably, food waste has enormous benefits for the planet if recycled correctly. Redirecting food out of the “cowboy” economy (landfills or incinerators) and into the “spaceman” economy transforms food waste from a terrible greenhouse generator to a decarbonization and regenerative agriculture weapon.

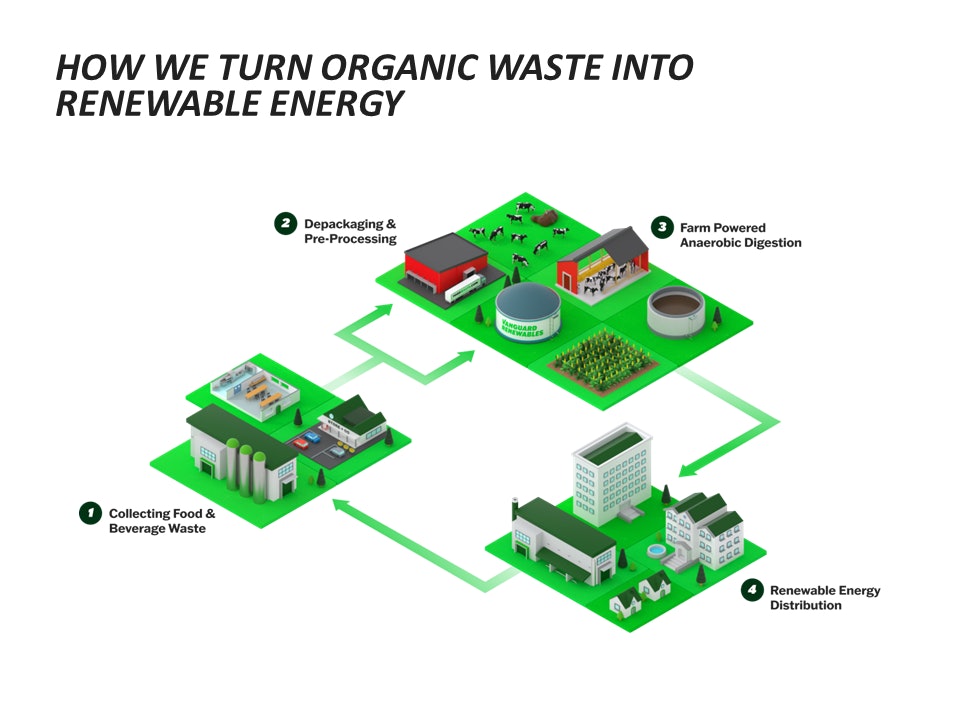

By working with food and beverage manufacturers to recycle their waste, Vanguard Renewables provides a circular solution for many of its partners. Polar Beverages and Cabot Creamery are two examples of companies successfully using a circular economic model to support their businesses and the planet.

Embracing circularity turns the byproduct from the food and beverage industry from bad to good.

Polar Beverages

Polar Beverages, based in Massachusetts, is a leader in the sparkling water and flavored soda marketplace and has been a first mover with their ESG initiatives. Polar has also set several goals to further shrink its carbon footprint in the coming years.

The company has minimized all raw materials and ensured that any used are 100 percent recyclable and has eliminated 31 percent of potential wasted material for its fridge-style packaging of 12-pack cases. Polar has also reduced its water usage by over 75 thousand gallons per day and has set a goal to increase that number to 125 thousand gallons by year-end. Polar continues to look at ways to reduce PET materials, already seeing a reduction of 7 percent with the advent of a new finish and cap in 2011 and 50 percent of PCR materials on 2-liter green bottles.

For circularity, Polar has engaged Vanguard Renewables to recycle its expired and off-spec materials at Vanguard’s Farm Powered® anaerobic digesters, where the nutrients are converted into renewable energy, organic fertilizer, and irrigation for Vanguard’s host farms. Vanguard Renewables receives the rejected materials and mechanically separates the liquids from the packaging, creating part of the daily feed for the microorganisms that produce renewable natural gas at its digester facilities. Polar then closes the circularity loop by using the renewable energy from the farm to power its manufacturing facility in Worcester, Massachusetts, since 2015.

As a result, Polar has a truly circular approach to both waste and energy management.

Cabot Creamery

Cabot Creamery, headquartered in Vermont, has long been a sustainability leader in the food and beverage industry. Much like Polar, the farmer-owned co-operative was an early adopter of Vanguard’s Farm Powered solution to recycle its inedible food waste to create clean, renewable energy and helping to mitigate the release of greenhouse gas into the atmosphere.

For over 100 years, Cabot Creamery has been working to sustain local dairy farms and help build strong communities. Cabot is dedicated to regenerative agriculture and sustainability and was the world’s first dairy co-operative to become a certified B Corporation. Happy cows make delicious dairy products! All these attributes and more personify a circular economy as defined by the Ellen MacArthur Foundation.

Cabot’s approach closes several loops. First, the Goodrich Dairy Farm in Salisbury, Vermont and Barstow’s Longview Farm in Hadley, Massachusetts are both Cabot Co-operative family farms that provide milk used in Cabot’s manufacturing processes and both host Farm Powered digesters. The waste created from Cabot’s manufacturing processes is returned back to the two farms. There, the anaerobic digesters convert the dairy byproducts into renewable energy, which is used to decarbonize Cabot and many other community members while the liquid portion returns the nutrients to the farm’s soils. Both farms have reported a significant increase in crop yield and nutrient value since converting to the circular fertilizer versus conventional sources.

In a true circular form, Cabot’s food waste becomes renewable energy that Cabot ultimately purchases to help reduce the carbon impact of its facilities and materially improve the financial and environmental sustainability of its farmers.

Closing Thoughts

I can’t help but think about how right Boulding was nearly 60 years ago about the future of our global economy.

Today, we are in a fight between the “cowboy” and the “spaceman” for the future of our planet. It has become essential that we accelerate our transition to a circular economy if we want to continue to have a habitable “Spaceship Earth” to live on.

Companies like Polar Beverages and Cabot Creamery Co-operative are working to keep our spaceship moving by closing the loop from the beginning to the end of their products’ life cycles. Their manufacturing waste not only creates renewable energy, but also provides New England dairy farms with added revenue from hosting a Farm Powered digester. The waste that is recycled through the Farm Powered process creates three unique benefits: renewable energy that powers factories, towns, and colleges; a low-carbon and organic fertilizer; and organic bedding made from the herd's biometrics that makes for happier and healthier cows.

Whether making a widget or a culinary treat, prioritizing a circular life cycle for products helps keep them out of waste streams until they are negligible, or better yet, they never land there.

-- John Hanselman, Chief Strategy Officer, Vanguard Renewables